Bringing New Life to Unwanted Items

By Chiachen Wu (吳佳珍)

Photos by Alberto Buzzola

Abridged and translated by Huang Yung-ping (黃永平)

Rosalind Chang (張薰云)

Bringing New Life to Unwanted Items

By Chiachen Wu (吳佳珍)

Photos by Alberto Buzzola

Abridged and translated by

Huang Yung-ping (黃永平)

Rosalind Chang (張薰云)

Each paver block Tsai invented is made of the plastic lining of around 350 paper containers.

Earth's natural resources are being depleted, and extreme weather conditions are becoming more and more common. If sustainable development is what we seek, it is imperative that we change our lifestyles and mindsets. For example, we can start by opening our minds to the fact that waste can be turned into valuable resources if we utilize them correctly.

The word "upcycling" was declared the 2019 Word of the Year by Cambridge Dictionary. According to the English dictionary, the definition of the word is "the activity of making new furniture, objects, etc. out of old or used things or waste material." Although its definition is rather general, there are some notable examples of upcycling in the textile industry, such as fabrics made from recycled plastic bottles.

Paver blocks made from recycled paper containers have been used in Hualien Tzu Chi Hospital, and in the future, they will be put to a wider use.

Increasing the value of recycled materials can help businesses enhance their profit and reduce the amount of waste generated. According to Dr. Lin Hong-yue (林宏嶽) from Chaoyang University of Technology, if companies make good use of recycled materials, they can become useful materials once again instead of being sent to incinerator plants or landfills as ordinary waste.

Upcycling Unwanted Items

In Taiwan, the annual consumption of disposable paper containers is around eight billion, and many of the used containers end up in an incinerator plant or a landfill. Based on the statistics of Taiwan's Environmental Protection Administration, 50 thousand tons of paper containers were recycled in Taiwan in 2018, with a recycling rate of 65 percent. However, whether all of the recycled containers are sent to processing plants or not is unknown.

Disposable paper containers are usually lined with a thin plastic layer to prevent liquids from seeping through the paper, so they have to be processed by specialized facilities. Currently, there are only three facilities in Taiwan that are capable of processing disposable paper containers. After processing, the pulp can be made into recycled paper, and the plastic linings can be made into plastic pellets, alternative fuel, or even paver blocks.

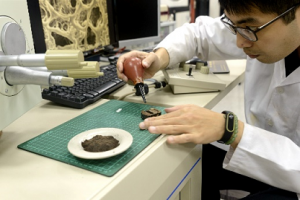

In 2019, Tsai Sheng-lun (蔡昇倫), the chief R&D officer of Jing Si Pureland Co., invented a new type of paver blocks made from the recycled plastic linings. The research and development process took him two years.

Recycled bottles get shredded and cleaned before they are melted, filtered, molded into the form of pellets and then cooled.

Being able to withstand a maximum weight of 40 tons, the paver blocks invented by Tsai are just as good as their regular cement counterparts. Although they cost more to manufacture, their production process does not require the use of new materials.

Earning International Recognition

The Taiwanese government has been promoting recycling since 1998, and recycled materials have long been in use. So, why didn't upcycling materials attract much public attention in the past? "Most people believe that recycled materials are subpar, and that they can only be used in a small proportion as a way of reducing production costs," Lu Chih-wei (呂智偉), engineer of Da Fon Environmental Technology, commented.

In the past, companies adopted recycled materials to reduce production costs because they were cheaper, but now, companies use them because they are better for the environment. The European Parliament has approved a new law, banning the usage of disposable plastic items by 2021 and demanding that plastic bottles be made with at least 30 percent of its materials coming from recycled sources by 2030. In addition, multinational corporations such as The Coca-Cola Company and Nike, Inc. have asked their suppliers to use recycled materials as well.

In 2019, Bailan, a Taiwanese laundry detergent brand owned by Unilever, chose to bottle its new products in containers made from recycled plastic pellets. The pellets are made by a company called Da Fon Environmental Technology Co., Ltd. By using recycled materials, Bailan can reduce the carbon emissions of their production process by 80 percent.

Recycled bottles have to be sorted manually before they can be processed into plastic pellets.

Da Fon Environmental Technology has been in the recycling business for almost two decades. It owns several recycling stations and processing plants, and its recycling stations receive more than half of the recycled PE and PP containers in Taiwan. Its engineers have developed a method to reuse recycled plastic. The recycled plastics are sent to the processing plants and transformed into plastic pellets.

As the company owns recycling stations all across Taiwan, it is able to secure a steady supply chain. In addition, to improve the quality of its pellets, the recycled plastics are sorted by color and deodorized. The company tries its best to increase the value of its products as much as possible to cover the expense of processing recycled materials.

However, the company had a rough start in the early years since it could not find any factories willing to cooperate with it. "Most factories refused to work with us after they learned that our pellets were made from recycled plastic. They believed that pellets made from recycled plastic would damage their machines. However, one factory eventually told us that there was no significant difference between our pellets and the ordinary ones. Two years later, several companies approached us, hoping to work with us. People were finally convinced that pellets made from recycled plastic were equally good and were willing to give them a chance," the deputy manager of the R&D department of Da Fon Environmental Technology commented.

The prices of most plastic pellets are volatile because they are influenced by the price of oil and regional economy, but the price of the pellets produced by Da Fon is relatively stable as it is made from recycled materials. In 2014, Da Fon was awarded the Blue Angel, a German certification that has been awarded to eco-friendly products and services since 1978. Some companies learned about Da Fon's products through the Blue Angel and became its client. Receiving international certifications has undoubtedly helped Da Fon increase the value of its recycled materials.

Differentiating Products from Other Competitors

While Da Fon focuses on using recycled material made from PP and PE items, some textile companies have already been investing in recycled materials for more than 20 years, mostly choosing to develop polyester fiber made from recycled plastic bottles. Today, polyester fiber made from recycled plastic bottles has become an important material for functional clothing.

The DA.AI Eco Blankets are made from black and white yarn, so they have a natural color of gray.

In theory, plastic bottles can be processed and made into pellets, which in turn can be made into synthetic fiber. However, in reality, recycled bottles usually contain impurities which may affect the quality of pellets and cause damage to production machinery. To solve this problem, DA.AI Technology asked volunteers working in Tzu Chi’s recycling stations to sort recycled bottles and remove bottle caps and rings before the bottles are processed. Through cooperating with more than sixty companies, it produces clothing with at least 50 percent of their fabric coming from reused materials.

In 2018, 140,000 metric tons of plastic bottles—equivalent to five billion bottles—were recycled in Taiwan, with 3,700 metric tons recycled by Tzu Chi's 8,000 recycling stations. Around 1.5 percent of all the recycled plastic bottles in Taiwan were processed by DA.AI Technology.

Most textile companies produce tens of thousands of clothes at a time, but DA.AI Technology can only produce hundreds of them at once. Therefore, it is crucial for its designers to make its goods different from that of other manufacturers, so most of its products are designed for disaster relief. DA.AI Eco Blankets, which are made from pure recycled polyester, are the most well-known examples. It takes 68 plastic bottles to make one blanket, and more than one million blankets have been distributed by Tzu Chi volunteers in more than 30 countries around the globe.

Although coffee grounds only make up a small portion of the yarn, they can add minuscule holes into the surface of the fabric, which help to absorb odors.

In 2009, Singtex Industrial Co., Ltd., a Taiwanese textile company founded in 1989, developed an eco-friendly yarn made from recycled plastic and coffee grounds. It was the first to add coffee grounds into yarn and were granted patents in Europe, the United States, Japan, Korea, China, and etc. Patagonia, Inc., The North Face, and New Balance are some of its clients.

Coffee grounds can make fabrics absorb odors and sweat, block ultraviolet light, and dry quicker. Grounds for three cups of coffee and five plastic bottles are enough to make one T-shirt.

Only a small amount of coffee grounds is needed to make a shirt, but processing them can be very tricky. First of all, the coffee grounds must be dried, and then, the oil in coffee grounds has to be removed, which is the most difficult part. At first, researchers thought it was nice that the shirts gave off the fragrance of coffee, but the coffee smell became nauseating after the sebum from the skin had been mixed in. As a result, they extracted the coffee oil and turned it into a waterproof material, fully utilizing its potential.

The textile industry is considered to be a major polluter because the traditional dyeing process produces a huge amount of wastewater. Therefore, both Singtex Industrial and DA.AI Technology have adopted a new approach to dyeing their fabrics. Instead of dyeing their fabrics, they dye the plastic pellets. Compared to the traditional method, their new approach uses only ten percent of the water required traditionally, consequently reducing the wastewater produced.

Although these products made from recycled materials have received numerous international certification for their greenness, it is still possible that they have caused pollution in some other ways. "To evaluate a product’s overall impact on the environment, it is better to use a technique called life-cycle assessment," Dr. Lin suggested. Life-cycle assessment allows experts to assess a product’s environmental impact in every stage of its life and find a way to mitigate the impact.

Dr. Lin said that based on the cases he had assessed before, the results indicated that using recycled materials is better for the environment. "Generally speaking, extracting, transporting, and processing new materials create a lot of pollution. Although using recycled material may create more waste, for instance the exhaust generated during the processing process, it saves materials and energy," he added.

Story Wear transforms secondhand jeans into fashionable clothing and accessories.

Transforming Old Items into New Ones

Lu has been in the plastics industry for decades, and he keeps a close eye on environmental issues. He pointed out that most people focus on whether the recycled waste gets reused or not, or ask what kinds of waste can be recycled. "However, these are not the ultimate solution to environmental issues," he said. What we should think about is how we can change our lifestyles instead of only placing emphasis on recycling.

Story Wear is a new Taiwanese clothing brand dedicated to sustainable fashion, and it wants to spread its idea to the general public. "It’s almost impossible for us not to buy new things, but if we can cherish our belongings more, we can avoid buying too much stuff," Chen Kuan, the founder of Story Wear, commented.

The pollution caused by producing new clothes is a major concern, but we should not forget about the problems caused by unwanted clothes. In 2018, more than 70,000 metric tons of garments were recycled in Taiwan, and the numbers continue to grow each year. Most of the recycled clothes are used as cleaning and insulation material; only a small amount gets sold overseas.

After working in the garment industry for many years, Chen left Taiwan for the United Kingdom to study sustainable fashion. Her experience in there made her believe that fashion and environmental protection should not be contradicting ideas. She visited a garment recycling station and noticed that most recycled clothes were shirts and jeans. Denim fabric is known for its durability, which makes it very suitable for modification. Hence, she started to work on transforming unwanted jeans into new clothes and bags.

Seventy percent of their materials come from garment recycling stations and donations, and thirty percent come from textile factories. Designers of Story Wear make designs for new products for local workshops to follow. One of the workshops, named Ant Meet Cat, consists mainly of mothers of cerebral palsy patients.

Tang Zhong-li (唐中利) has been doing needlework for more than twenty-five years, and she is the instructor of Ant Meet Cat. "At first, we were looking for products suitable for our children, but we could not find any. So, we decided to make them ourselves. After a while, we began to tailor secondhand clothes," she said. It is impossible for these moms to work full-time and take care of their children at the same time; therefore, they started to work as tailors and upcycle used clothing.

The founders of CULTU-RE turn recycled material into notebooks, bags and other creative accessories.

CULTU-RE is another Taiwanese company dedicated to upcycling and sustainable development. Lo Sheng-Yen (羅盛彥) and his wife Chen Nai-yun (陳乃韻), founders of CULTU-RE, collect used cardboard boxes, school uniforms and advertising canvases and turn them into notebooks, bags and cup sleeves. After three years of hard work, their products have started to attract attention from costumers. "Retailers told us that our products are quite popular among Japanese tourists, and they asked us if we could speed up our production," Chen smiled as she said this. However, Lo remarked that mass production would pose a real challenge to them since the production process is too complicated, and they cannot find a factory that will take their order.

Although the materials they use are not costly, processing them requires a huge amount of effort. Lo and Chen have both sustained injuries while processing the materials, however, they remain committed to their company goal, which is to upcycle used materials.

Saving Our Environment in More Than One Way

When it comes to upcycling, the concept of a circular economy is often mentioned. According to the British Standards Institution, a circular economy means an economic model where resources are recovered at their highest quality and kept in circulation for as long as possible.

Yet, many people only focus on the "circular" part of recycling, without paying attention to the economy behind it. Dr. Yeh Shin-cheng (葉欣誠) from National Taiwan Normal University pointed out that to solve environmental issues, we have to take both the economic and societal aspects into consideration.

Tzu Chi volunteers in Taiwan demonstrate how blankets can be made from recycled plastic bottles.

He suggested that to create a practical circular economy, products made from recycled materials need to be reasonably profitable. "Recycled waste around the world can be useful materials as long as its quality is good and is fairly low-priced," Dr. Yeh stated. Dr. Yeh's comment also involves the issue of waste import, which has been a controversial subject in Taiwan over the past two years.

"All materials can be made into something else. I believe it’s possible for us to process imported waste and sell them at a decent price," Dr. Yeh remarked. Some people have the misconception that importing waste is welcoming pollution to our doorstep. However, as long as we can establish an effective pollution control system, importing waste can be an opportunity to boost our economy while protecting our environment.

The Taiwanese government has imposed a restriction on the types of waste that can be imported and also approved a law which demands that domestic wastes have to be processed first before any foreign waste is imported.

Waste import allows companies in the recycling business to increase their scale, but the controversy remains the same. Should we import waste or not? "The answer to that question varies from person to person. It is still unclear if Taiwan's environment can accommodate imported waste," Dr. Lin commented.

Although money and profit may be the strongest motivation behind some people's actions, they should not be the only reason why we do recycling work. Instead, achieving a sustainable development and coexisting with the Earth should be our ultimate goal.

Contact Us | Plan a Visit | Donate

8 Lide Road, Beitou 11259, Taipei, Taiwan

886-2-2898-9999

005741@daaitv.com

©Tzu Chi Culture and Communication Foundation

All rights reserved.